Lenovo聯想深圳工廠介紹

2020-05-19 09:45:44 來源: 點擊:

聯想深圳工廠扎根深圳30多年,最早可追溯到1987年長城計算機集團PC主機廠,94年,長城與IBM成立合資公司。2005年,聯想收購IBM全球個人電腦事業部,深圳工廠PC制造加入聯想。2014年,隨著聯想再次收購IBM X86服

聯想深圳工廠扎根深圳30多年,最早可追溯到1987年長城計算機集團PC主機廠,94年,長城與IBM成立合資公司。2005年,聯想收購IBM全球個人電腦事業部,深圳工廠PC制造加入聯想。2014年,隨著聯想再次收購IBM X86服務器業務,服務器制造也加入聯想。如今,深圳工廠已成為聯想集團出口海外的重要生產基地,肩負聯想商業PC和服務器業務全球170多個國家的供應重任,為聯想集團全球化業務提供強有力支撐。

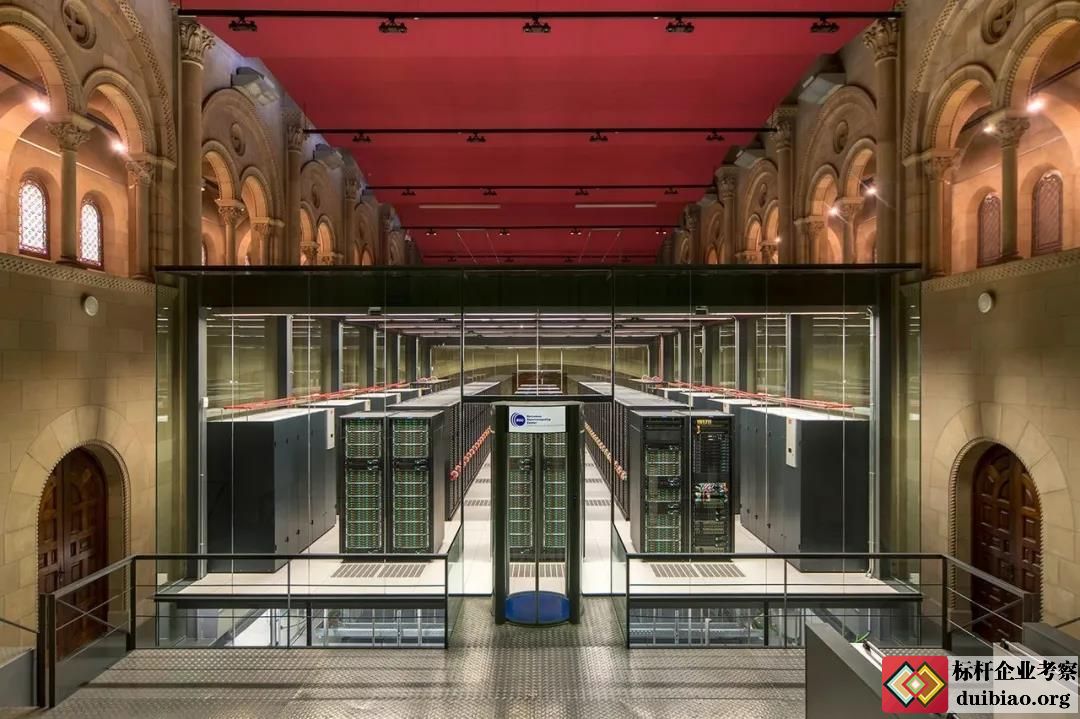

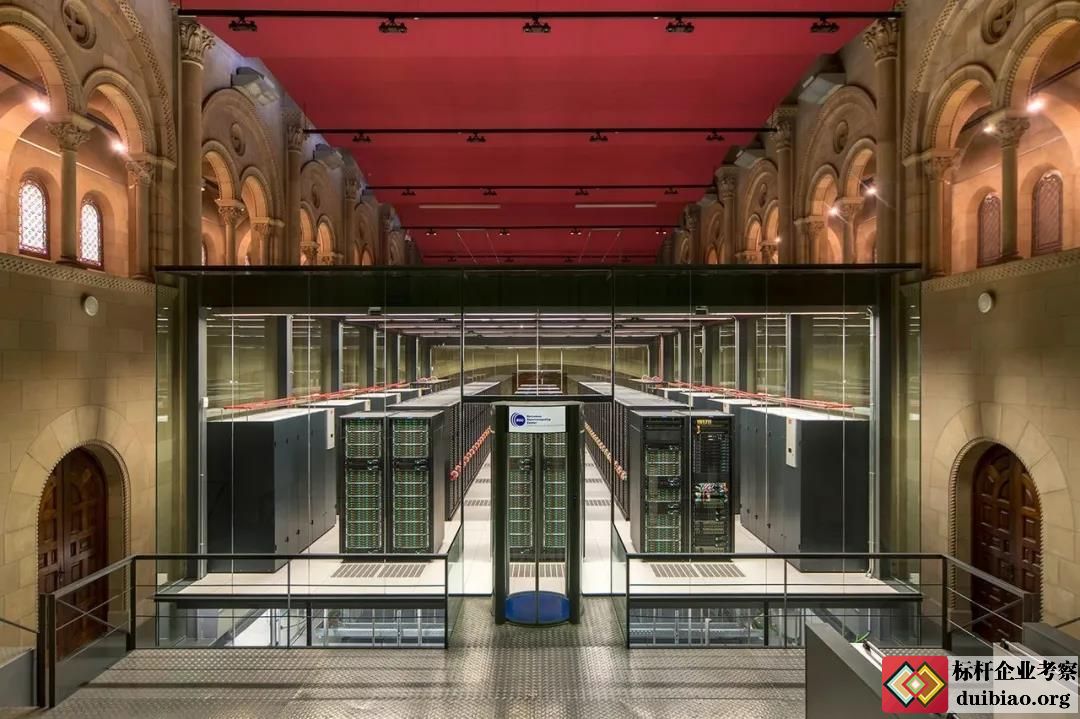

深圳工廠是聯想全系列商業產品的重要生產基地,產品涵蓋高端商用筆記本、臺式機、一體機、工作站、刀片式服務器、邊緣計算服務器、高性能服務器、水冷式服務器、大型機柜,超大型機柜集群以及各種選件產品,為微軟、IBM、法國郵政、亞馬遜、豐田、谷歌、BAT,京東等上百家超大型跨國公司客戶提供定制產品,是一家供應全球計算力產品的生產基地。2018年,全球領先的巴塞羅納超算中心的產品正是來自這里。

深圳工廠也是一家高度柔性化、個性化的工廠,它每天24小時不間斷接收來自全球170多個國家的上萬張訂單;在20多年的生產過程中保質保量按時交付,截至目前,累計產品出貨量超1億臺。

制造力驚人,源于智造力不凡——工廠自我開發的樂MES系統與I-TAC系統,可以實現端到端產品信息追蹤與質量狀態全程監控。同時,工廠通過模擬仿真技術進行線體設計與優化;利用IoT技術搭建工廠物聯網;導入各種自動化技術持續提升工廠自動化率。利用控制器、傳感器等技術采集生產運作數據,持續優化生產運作方式。

深圳工廠也是一家高度柔性化、個性化的工廠,它每天24小時不間斷接收來自全球170多個國家的上萬張訂單;在20多年的生產過程中保質保量按時交付,截至目前,累計產品出貨量超1億臺。

制造力驚人,源于智造力不凡——工廠自我開發的樂MES系統與I-TAC系統,可以實現端到端產品信息追蹤與質量狀態全程監控。同時,工廠通過模擬仿真技術進行線體設計與優化;利用IoT技術搭建工廠物聯網;導入各種自動化技術持續提升工廠自動化率。利用控制器、傳感器等技術采集生產運作數據,持續優化生產運作方式。

在質量控制方面,工廠與全球領先的零部件企業合作,從源頭保證部件的高品質;與世界一流研發團隊深度合作,參與前端產品的設計與制程開發并進行嚴格驗證;制程通過可智能防錯防呆的各類管控系統、嚴酷的可靠性測試、模擬客戶使用XCSA測試等,保證最終產品的卓越品質。

深圳工廠每年都要接受專業第三方審核機構、全球客戶及中外政府審核50次以上,憑借過硬的質量,安全,環保,勞工等系統管理體系順利通過各項嚴格審核,從而助力深圳工廠獲得全球170多個國家和地區的市場準入資質與全球客戶訂單。

放眼未來,深圳工廠將秉承 “以客戶為中心”、 “以人為本”、“智能制造”的核心理念,致力于建設行業領先的數字化智能制造基地,打造智能制造標桿企業,助力聯想全球化業務的開展,將工廠打造成深圳這個國際化創新城市的“價值”工廠!

翻譯版

Lenovo Shenzhen Plant Introduction

Dedicated in Shenzhen for over three decades, the Lenovo Shenzhen Factory can be traced back to year 1987 when it was the PC mainframe factory of Great Wall Computer Group. In 1994, the Great Wall Computer Group established a joint venture with IBM. In 2005, Lenovo acquired IBM's Global PC Division and Shenzhen factory’s PC manufacturing business was incorporated into Lenovo. In 2014, with Lenovo acquiring IBM X86 server business, IBM’s server manufacturing business was also incorporated into Lenovo. Today, the Shenzhen Factory has become an important production base of Lenovo Group, shouldering the burden of supplying Lenovo's commercial PC and server business in more than 170 countries around the world, providing strong support for Lenovo Group's global business.

The Shenzhen Factory is an important production base for Lenovo's all-series commercial products, including high-end business notebooks, desktops, all-in-one machines, workstations, blade server, edge computing servers, high-performance servers, water-cooling servers, Racks, Rack Clusters, and other PC and server options. It also produces customized products that fulfill the demands of multinational companies around the world such as Microsoft, IBM, France Post, Amazon, Toyota, Google, Alibaba, Tencent, Baidu, JD, etc., making it a truly global production base for computing power products. In 2018, the products of the world's leading Barcelona Supercomputing Center was produced here.

The Shenzhen Factory is also a highly flexible and personalized factory that receives tens of thousands of orders from more than 170 countries around the world 24 hours a day. In the production process of more than 20 years, there has been no delay in delivery with quality and quantity guaranteed. By the beginning of 2019, the cumulative business PC shipments have exceeded 100 million.

The amazing manufacturing power stems from the extraordinary intelligence and creativity. The self-developed LE-MES system and network platform can realize end-to-end product information tracking and quality status monitoring. The Factory designs and optimizes the production line through simulation technology. Using IoT technology, the Factory builds its Internet of Things. It adopts various automation technologies to continuously improve its automation rate. It also utilizes technologies of controller and sensor to collect production operation data so as to continuously optimize its production operation.

In terms of quality control, the Factory cooperates with the world's leading component companies to ensure the high quality of components from the source; it deeply cooperates with the world-class R&D team, participates in the design and manufacturing process development of front-end products and conducts strict verification; the manufacturing process ensures the excellent quality of the final product through various control systems that can intelligently preform error-proof and fool-proof, rigorous reliability testing, and XCSA testing by simulating customer usage.

The Shenzhen Factory accepts audits by professional third-party auditing institutions, global customers and Chinese and foreign governments for more than 50 times every year. With excellent quality, safety, environmental protection, labor and other system management systems, the Factory has passed various strict audits, allowing it to obtain market access qualifications and global customer orders from more than 170 countries and regions around the world.

Looking forward to the future, the Shenzhen Factory will adhere to the core philosophy of "customer-centered", "people-oriented" and "smart manufacturing" and will be committed to building the industry's leading digital intelligent manufacturing base, creating an intelligent manufacturing benchmarking enterprise, facilitating the development of Lenovo's global business, and building the Factory into a "valuable" factory of Shenzhen, an international innovative city!

上一篇:走進深圳傳音總部 考察新基建時代下的零售趨勢解析

下一篇:考察安徽合肥標桿企業介紹

深圳工廠也是一家高度柔性化、個性化的工廠,它每天24小時不間斷接收來自全球170多個國家的上萬張訂單;在20多年的生產過程中保質保量按時交付,截至目前,累計產品出貨量超1億臺。

深圳工廠也是一家高度柔性化、個性化的工廠,它每天24小時不間斷接收來自全球170多個國家的上萬張訂單;在20多年的生產過程中保質保量按時交付,截至目前,累計產品出貨量超1億臺。